In much the way as Lean methodology and Six Sigma synergise into Lean Six Sigma to form a perfect partnership, so, too does Lean Six Sigma with the EFQM Model and its fundamental concepts.

Let’s start by looking at the relationship between Lean and Six Sigma and the formulation of Lean Six Sigma.

We need to adopt thinking that focuses on improving value for the customer, by improving and smoothing the process flow, and eliminating waste. Since Henry Ford’s first production line, Lean Thinking has evolved through a number of sources, and over many years, but much of the development has been led by Toyota through the development of the ‘Toyota Production System’. They were able to build on Ford’s production ideas, moving from ‘high volume, low variety’, to high variety of choice with low volumes.

The five key principles of Lean Thinking are set out below:

- Understand the customer and their perception of value

- Identify and understand the value stream for each process and the waste within it

- Enable the value to flow

- Let the customer pull the value through the processes, according to their needs

- Continuously pursue perfection (continuous improvement)

Six Sigma thinking complements these principles through a systematic and robust method to improvement, based on management by fact, and also focused on the customer and key stakeholders. If we are to deliver the best customer experience, we have to listen to and understand the ‘Voice of the Customer’. We can then make sure that the objectives of our services and processes are appropriately focused.

Measurement and management by fact enables more effective decision-making, and by understanding variation we’ll also know when to take action and when not to. Of course, to be truly effective, we need to involve the

people in the process, equipping them to be able, and feel able to challenge and improve their processes and the way they work.

The evolution of Six Sigma began in the US, championed firstly by Motorola in the manufacturing environment and then General Electric, under its then CEO, Jack Welch, who realised its applicability to all business sectors and extended its reach into the services sector and thus the totality of the markets served by his organisation.

The five key principles of Six Sigma are:

- Understand the critical to quality requirements (CTQs) of our customers and stakeholders

- Understand our processes ensuring they reflect these CTQs

- Manage by fact

- Involve and equip the people in the process

- Undertake improvement activity in a systematic way

As you can see, there is both similarity and synergy between Lean and Six Sigma, and a set of Lean Six Sigma key principles emerge that reflect the best of these two approaches. The principles are:

- Focus on the customer

- Identify and understand how the work gets done – the value stream

- Manage, improve, and smooth the process flow

- Remove Non-Value-Add steps and waste

- Manage by fact and reduce variation

- Involve and equip the people in the process

- Undertake improvement activity in a systematic way

Let’s take a brief look at these principles:

- The key focus is on the customer. You need to understand their perception of value, and their CTQs. The CTQs provide the basis for your measurement set which will help you understand how well you are performing against these critical requirements. Focusing on the customer, and the concept of Value-Add, is especially important as typically, only 10 – 15% of process steps add value, and often represent only 1% of the total process time.

- By identifying and understanding how the work gets done – the value stream, you can highlight the Non-Value steps and waste. In doing so, you can ensure the process is focused on meeting the CTQs and adding value. To do this properly, you have to go to the ‘Gemba’. This Japanese word is usually associated with the workplace – where the work gets done, or where the action is. And that’s where management begins. Process Stapling involves doing just that to see how the work really gets done, not how we think it gets done, or how we’d like to think it gets done! So go to the workplace to see the real process being carried out, and collect data on what’s happening. You’ll find this will make it easier for you to analyse the problem in your DMAIC improvement project, (the robust improvement method – Define, Measure, Analyse, Improve, Control) and will help you determine a more effective solution. Understanding, managing and improving the value stream is key as it sets out all of the actions, both value creating and Non-Value creating, that bring a product or service concept to launch. And bring a customer order through supply chain processing to delivery. These include actions to process information from the customer, and actions to transform the product on its way to the customer. Toyota’s Taiichi Ohno describes the approach very effectively: “All we are doing is looking at a time line from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that time line by removing the Non-Value-Added wastes.”

- Managing, improving and smoothing the process flow provides another example of different thinking, something that is equally applicable to both service and manufacturing organisations. If possible use single piece flow, moving away from batches, or at least reducing batch sizes. Either way, identify the Non-Value-Added steps in processes and try to remove them – certainly look to ensure they do not delay Value-Adding steps. The concept of pull, not push, links to our understanding the process and improving flow. And it can be an essential element in avoiding bottlenecks. Overproduction or pushing things through too early is a waste.

- Removing Non-Value-Add steps and waste is another vital element in improving performance. One way to improve flow and performance, generally, is to identify, remove, and prevent waste or, as the Japanese call it, Muda. They describe two broad types and seven categories of waste.

- Managing by fact, using accurate data, will help you avoid jumping to conclusions and solutions. You need the facts, and that means measuring the right things in the right way. Data collection is a process and needs to be managed accordingly. Using Control Charts will enable you to interpret the data correctly and understand the process variation. You will then know when to take action and when not to.

- Involve and equip the people in the process. If everyday operational excellence is to become a reality, it’s essential that people feel engaged. Managers and team leaders need to understand that their role is to work on their processes with the people in the processes to find ways of continuously improving performance. In effect, the people in the process need to feel that they’re able to challenge and improve the process and the way they work.

- Undertake improvement activity in a systematic way means not jumping to conclusions or solutions. There are two frameworks for this, DMAIC and DMADV.

DMAIC addresses problems with existing process, product and service; DMADV is used to design new processes, products and services:

[twocol_one]

Define – what do you think needs improving?

Define – what do you think needs improving?

Measure – use facts and data to understand how your processes work and perform

Analyse – use facts and data to determine the root cause(s) inhibiting your performance to the customer

Improve – identify, select, and test the most appropriate solution(s), validating your approach with data

Control – implement the solution and use data to help you hold the gains, and prompt new opportunities

[/twocol_one]

[twocol_one_last]

Define – this is about organising and planning the journey

Define – this is about organising and planning the journey

Measure – this focuses on the clarifying customer needs and translating them into measurable design goals

Analyse – we’ve established the ‘what’ now we ne3ed to determine the ‘how’ generating design concepts

Design – here we’re developing more detail around the design concepts and getting ready to pilot the design solution

Verify – the focus is on piloting and full scale implementation, verifying the results against the original design aims and CTQs

[/twocol_one_last]

So, Lean Six Sigma provides a rigorous and structured approach to help manage and improve performance. It helps you use the right tools, in the right place, and in the right way, not just in improvement and design projects, but also in your day-to-day activities. It really is about getting the key principles and concepts of Lean Six Sigma into the DNA and lifeblood of the organisation, so that it becomes a natural part of how you do things.

But is this also a natural part of the EFQM Model and its Fundamental Concepts? Let’s take a look:

Adding Value for Customers – Excellent organisations consistently add value for customers by understanding, anticipating and fulfilling needs, expectations and opportunities. Seeking to add value is an integral part of Lean Six Sigma that links to the importance of establishing and meeting the critical to quality requirements of the customer, the CTQs.

Creating a Sustainable Future – Excellent organisations have a positive impact on the world around them by enhancing their performance whilst simultaneously advancing the economic, environmental and social conditions within the communities they touch. Lean Six Sigma drives improving performance through its comprehensive toolkit and the DMAIC and DMADV frameworks.

Developing Organisational Capability – Excellent organisations enhance their capabilities by effectively managing change within and beyond the organisational boundaries. The importance of managing change in engaging people and stakeholders, generally, cannot be overstated. An integral part of Catalyst’s Lean Six Sigma relates to managing change and the work of John Kotter and George Eckes’ E = Q x A formula for instance support effective change management.

Harnessing Creativity & Innovation – Excellent organisations generate increased value and levels of performance through continual improvement and systematic innovation by harnessing the creativity of their stakeholders. Creativity and innovation are at the heart of the DMADV framework which is sometimes referred to as ‘Design for Six Sigma Performance’. Harnessing the creativity of people, generally, is a natural element in continuous improvement and therefore in DMAIC projects, too.

Leading with Vision, Inspiration & Integrity – Excellent organisations have leaders who shape the future and make it happen, acting as role models for its values and ethics. Lean Six Sigma supports strategy deployment and Catalyst has developed the DRIVE framework (Define, Review, Improve, Verify, Establish) to help facilitate and manage an organisation’s journey to its true north:

Define – you’ve recognised where you want the organisation to be – its ‘True North’.

Define – you’ve recognised where you want the organisation to be – its ‘True North’.

Review – check and assess the organisation’s capability to achieve the change needed.

Improve – this phase has three parts that look to prepare for the journey, shape and scope what needs to be done, and then implement the agreed actions and projects.

Verify – you are monitoring progress and performance against plan ensuring that you are on track.

Establish – ensure the gains made are held as you seek to embed the new ways of working into the organisation’s DNA.

You can find out more about DRIVE in ‘Lean Six Sigma Business Transformation For Dummies’.

Managing with Agility – Excellent organisations are widely recognised for their ability to identify and respond effectively and efficiently to opportunities and threats. Lean Six Sigma provides a rigorous means to help support the organisation implement the actions needed to respond appropriately.

Succeeding through the Talent of People – Excellent organisations value their people and create a culture of empowerment for the achievement of both organisational and personal goals. As we indicated earlier, Lean Six Sigma looks to equip the people in the process enabling them to feel that they’re able to challenge and improve their processes and the way they work. Organisations cannot afford to waste the potential of their people, nor should they fail to recognise the strong statistical correlation between employee and customer satisfaction.

Sustaining Outstanding Results – Excellent organisations achieve sustained outstanding results that meet both the short and long term needs of all their stakeholders, within the context of their operating environment. This is what Lean Six Sigma is striving to do. What’s more the ‘control phase’ of DMAIC, the ‘verify phase’ of DMADV and the ‘establish phase’ of DRIVE aim to help organisations ensure their improvement gains are maintained – it’s all too easy for performance to slip.

The EFQM Fundamental Concepts of Excellence outline the essential foundations for achieving sustainable excellence and the link to Lean Six Sigma seems clear.

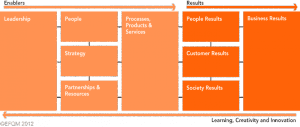

Working with the EFQM Excellence Model we can clearly distinguish two parallel streams organisations use to drive results – the process (or ‘hard’) stream, and the culture (or ‘soft’ stream).

In the first stream, Leadership develops and deploys the Strategy of the organisation through organising the business, and how processes are designed, improved and operated through to delivering against the targeted Business Results. People then operate those core processes to manage inputs from Partners and Suppliers, and other Resources to produce, deliver and support products and services to and for Customers, meeting their requirements and thereby generating cash and profits for the business. Lean Six Sigma is the generally accepted best practice approach to improving and designing processes which are at the core of this strand.

In the second parallel stream, the same Leadership drives the enterprise’s Vision and Values developing a culture that engages, motivates and rewards the People to manage relationships ‘with a smile’ with all relevant Stakeholders and in particular with the customers of the business. Positive client relationships building on consistent operational product and service delivery then satisfies, indeed delights, customers, creating a virtuous circle of repeat and increased business, good and improving profit margins, and sustained financial performance. Change Management is the generally accepted best practice approach to improving how people and customers are influenced to support this strand.

Of course, these streams are also interdependent at each stage as they flow from Leadership through to Business Results; an effective Strategy requires an appropriate business culture and environment, people need to feel valued to work well, supported with clearly defined roles and appropriate and timely resources, so that their engagement and enthusiasm flow through to customers – but no amount of this will compensate for poor service or product delivery.

Aligned processes are necessary for sustained results, but alignment of Values across the enterprise can dramatically enhance consistency of decision making; taken together they are the platform for consistently delivering what the customer seeks which in turn generates the desired financial results.

Synergising how the two strands work together is reflected in the E = Q x A equation – Effectiveness is the product of the Quality of Improvement (in the technical ‘fit for purpose’ sense) and the Acceptance of it by those affected. This draws together Lean Six Sigma and Change Management into approaches that drive improvement supporting and synergising both strands of the enterprise’s Management system.

Let’s look at what this can mean in practice:

One client, a global aerospace manufacturer’s experience of using the EFQM Model to assist in defining its improvement plan and then introducing Lean Six Sigma as its improvement method found the synergy of the two mechanisms as follows: the EFQM provided a comprehensive and rigorous approach to identifying the “what” to focus on (and therefore feed the Lean Six Sigma project hopper but in relation to the organisation’s strategy) and Lean Six Sigma provided the “how” to make the necessary improvements in a systematic and sustainable manner.

There seem to be so many organisations that are able to identify their ‘areas for improvement’ but who are unsure about how to address them. This is where Lean Six Sigma comes into play, be it a DMAIC or DMADV project that’s needed. These frameworks can also be applied in addressing cultural issues.

Another of my clients has recently used the DMAIC process to address differences in the performance of three different teams, each actioning the same work activities using a common process. Analysis showed the difference in productivity between the top performing team and the bottom amounted to almost 10%.

The project reduced this difference to less than 1% resulting in a financial benefit of just over one million Euros.

This article was originally published in the EFQM’s Excellence in Action publication: Achieving Sustainable Excellence

This article was originally published in the EFQM’s Excellence in Action publication: Achieving Sustainable Excellence